Overview of Egg White Powder

Egg white is the aqueous part of an egg. It is the raw ingredient from which albumen is obtained. Egg white consists of 10% dissolved materials and 90% water. Half of the dissolved material is protein, and it also contains vitamins and minerals. From a culinary perspective, the main characteristics of egg white are coagulation at 60°C and foaming. The proteins in egg white can form a foam. The higher the protein content, the better this works. From a food science perspective, egg white is mainly protein. Technologically, the proteins in egg white are used for emulsification, foaming, and stabilization.

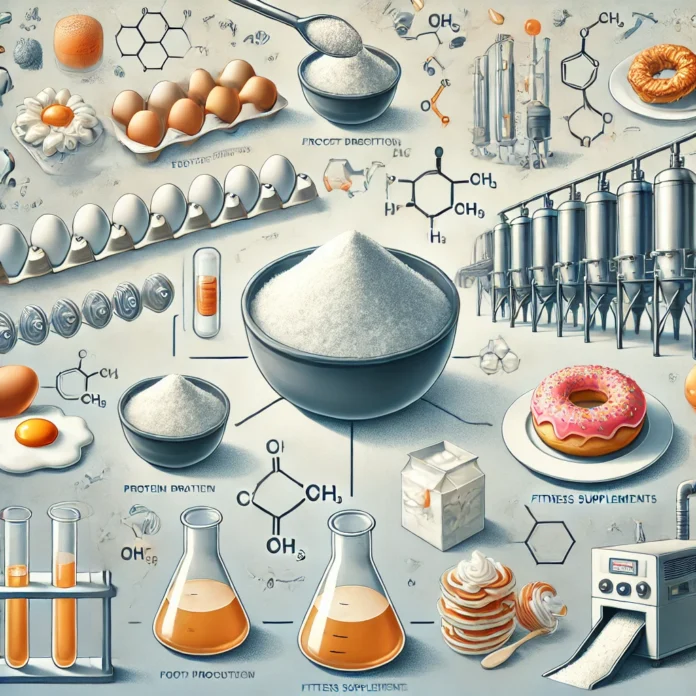

Uses of Egg White Powder

Egg white powder is used in sweets, mayonnaise, milk drinks, and desserts. The dried form, egg white powder, is the focus of this text. Egg white powder is available in a free-flowing form, which makes working with it easy and fast. It is affordable and easy to use. In terms of structure, egg white powder is used in rockery and marzipan, while its adhesion function is important. In Japan, egg white powder is preferred over egg white as a flour replacement because egg whites are imported and egg white powder is easier to store. As a dried form of egg white, it is used in bakeries and confectioneries as a raw ingredient. Egg white powder retains the same technical functions as natural egg white. It turns white after coagulation, similar to natural egg white, and is used as a raw material for supplements. It has gained attention from gym enthusiasts and consumers seeking high-protein diets. Several commercial brands of egg white powder are available, along with egg white and casein, followed by whey protein.

Production Process of Egg White Powder

The production process begins with sourcing eggs that meet prescribed quality criteria. The eggs must be in good and marketable condition. Quality control steps are carried out to exclude imperfections or contaminants. Bad eggs should not be processed. The next step involves separating egg whites from yolks to produce egg white liquid. Various techniques are used for isolation, focusing on accuracy and minimizing contamination through automation and validated equipment. The egg white liquid is pasteurized according to specific parameters and guidelines. Pasteurization is necessary to kill potential pathogens, extend shelf life, and increase safety. The liquid is then transformed into powder through a dehydration process in a spray dryer. Dehydration provides a longer shelf life compared to chilling or freezing while maintaining biological safety. Grinding is also part of the production process, and the powder is packed in packaging materials that reduce oxygen inflow to conserve quality.

Different techniques in egg white powder production prioritize hygiene and shelf life. However, the impact of specific working parameters, raw material preparation, or reconstitution on quality has been studied in detail only in the last two decades. Since 2002, egg white powder production processes have been developed to retain properties such as foaming, gelling, and protein network characteristics at the same level as fresh egg white. Older production techniques, especially those at higher temperatures, negatively affected egg white characteristics due to protein denaturation. Early methods often had limited gelation characteristics, making egg white powder unsuitable except for aerated and high-heat treated foams. Recent scientific advancements have focused on reducing waste and transformation-related costs. Technological improvements have enhanced hydration-dehydration equipment for egg and derivatives. Each technological step must be carefully managed to avoid damaging delicate proteins and other egg white constituents. Attention to these details allows manufacturers to produce egg white powder with consistent gel-forming characteristics, better flavor retention, and enhanced creaminess in custards.

Health Benefits and Nutritional Advantages

Egg white powder provides an additional source of nutrients for a healthy, balanced diet. Eggs are a high-quality source of protein, and egg white complements dietary patterns for weight management, strength development, and muscle repair. Essential amino acids in egg white are present in the same ratio needed by the human body for muscle maintenance and repair, including leucine, which is vital for muscle development. Egg white is low in fat and energy but rich in vitamins and minerals. Eggs are also a valuable source of choline, important for metabolism, cell structure, liver function, and lipid transport. Other valuable nutrients include vitamin B12, selenium, iodine, and riboflavin.

Including egg white powder in a balanced diet offers numerous benefits. It helps manage body weight by offsetting hunger. Leucine in egg white stimulates muscle protein synthesis and repair, beneficial for those engaged in resistance exercise or seeking hypertrophy. Egg white is a complete protein, containing all essential amino acids required for growth and repair, and is an effective way to increase protein intake and promote fullness. It is lower in fat and energy than most other protein sources, supporting weight management. Additionally, egg white is versatile and can be used as a protein ingredient in many dishes. It is also a valuable protein source for individuals avoiding dairy or those with lactose intolerance. These benefits make egg white powder appealing to those committed to a healthy, well-nourished, and active lifestyle.

Functional Properties in Food Applications

Egg white powder exhibits several functional properties based on the secondary and tertiary structure of its major protein, allowing it to unfold and combine with other molecules. Foaming properties are determined by disulfide bonds that provide strength and withstand whipping. The emulsifying properties are useful when a foam film mixes with fat droplets, stabilizing the emulsion. Gelling properties cause unfolding and interaction with subunits, allowing foamed and/or emulsified structures to harden. In food applications, these properties result in increased volume, lightness, and mouthfeel, as well as the ability to bind water and fat. Many foods can be aerated, gelled, and bound using egg white powder. Disulfide bonds allow gels to recover their oxidative bonds if broken or inhomogeneously formed, increasing strength.

Textural effects are crucial for food acceptance, particularly for bakery goods and confectionery, which rely on air bubbles’ formation and stabilization. Egg white powder can be used in various foams/products such as French meringues, Swiss meringues, mousse, protein bars, pavlova, flavored coatings, marshmallows, and dairy desserts. Processing conditions can alter functional/foaming characteristics, such as through Maillard reactions and lipid oxidation, which increase hydrophobicity, reduce water and fat creaming, and improve foam formation. EWP modification with molecules like starch can bind released water, affect product expansion during baking, and reduce the glass transition phase of expanded products. Glycated EWP-based meringues have reduced fat migration, cream more rapidly, and have a higher volume than non-glycated EWP-mix meringues. The addition of glycated EWP components to gluten-free bread affects softness, volume, and shape. EWP is also used in gluten-free bakery products, which often include gums, dietary fibers, and hydrocolloids for moisture retention. In dough systems like French baguettes, EWP impacts the bread-making process, volume, and shape.

Storage and Handling of Egg White Powder

To maintain egg white powder in good condition, follow these storage conditions and guidelines. Store in cool, dry environments. Warm or humid conditions increase the risk of mold and bacteria growth. Ideal storage temperatures are between 50°F to 70°F (10°C to 22°C). Egg white powder is hygroscopic and rapidly absorbs water from the air. Therefore, store it in opaque, heat-sealed packaging that is moisture, vapor, and air-resistant with minimal puncture.

When using powdered egg whites, ensure proper hydration by blending the powder with twice its weight in water. This prevents under or over-hydration in the final product. Monitor expiration dates and check for signs of spoilage such as discoloration, odor, or clumps. If contamination occurs, stop using the product immediately. In commercial settings, manage inventory to minimize waste from outdated products.

Can egg white powder be used as a means to clean silver from tarnish?

Yes, egg white powder can be used to clean silver from tarnish, though in an unconventional way. Egg whites contain natural substances that can help remove dirt and stains. To use this method, you can mix egg white powder with a bit of vinegar or lemon juice to create a paste. Apply the paste to the silver with a soft cloth and gently rub it. Afterward, rinse the silver with water and dry it thoroughly.

However, you should be cautious with this method, as it may have varying effects on different surfaces or materials. It’s a good idea to test it on a small, inconspicuous area first.